Rigid Rail Systems

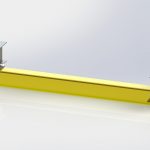

Webb-Rail

Webb-Rail offers a versatile High strength lightweight anodized aluminum rigid rail system that can be used indoors or outdoors. The enclosed track reduces snow, ice, dust and debris build-up compared to exposed beam flange trolley systems. The rail is typically utilized independently with hangar brackets or with fabricated truss supports from rolled structural shapes to span longer distances in most applications.

- High strength, lightweight structural aluminum ensures structural dead loads from the system are kept to a minimum.

- Trolley wheels equipped with sealed bearings providing effortless travel along the system.

- Available as single rail systems or dual rail systems to allow greater versatility and range of movement for workers

The Webb-Rail System allows the retractable lifeline/lanyard to remain overhead at all times, completely eliminating any potential for an in-line swing-fall. The enclosed track completely reduces dust and debris build-up, ensuring the system is readily available for use in spite of precipitation and weather conditions. The Teflon wheels of the sealed bearing trolley reduce wear and abrasion without damaging the anodized coating. A life expectancy of 25 years is not uncommon in most industries.

Trolley-Beam Systems

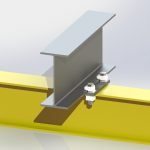

The Trolley-Beam systems are wide flange beams engineered for each specific application to provide fall protection for workers. The beam trolley systems are a preferred solution for indoor or outdoor applications where there is minimal deposit of debris and precipitation on the beam flanges. The flexibility of system design allows for multiple worker configurations, long span distances, and specialized/custom features. In most cases, the beams are attached via clamped connections to the existing structural members to ensure structural capacity is not decreased.

Motorized options

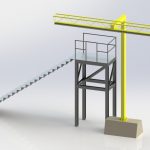

When the application does not allow for the rigid systems to be attached directly to the existing building structure overhead, the system is designed with pivot jib arms fixed to free standing columns or existing building columns. The pivot arms are motorized to “extend” or “retract” the I-beam trolley system, offering flexibility for facility operations. This also ensures that the operational envelope of cranes and other overhead equipment being utilized are maintained.